Working Principle:

SXQM series planetary ball mill working principle: There are two larger planetary rollers that make rotation movement installed on a base turntable which makes revolution movement. Another two smaller turntables are installed on each larger tank rollers respectively; there are two mill tanks on each smaller turntable. The machine has totally four ball tanks installed on the smaller turntables. When the base turntable rotates, the tank roller makes planetary movements. The balls and samples of material inside the tanks are ground and mixed under high speed movement.

Applications:

SXQM series of dual planetary ball mill is a kind of essential devise for labs, which want to mix, grind or produce high-tech new material in small lot. It is widely used in the following industries such as electronic, magnetism, medicine, ceramic, geology, mineral, metallurgy, build material, chemical, light industry, beauty, environmental protection, and etc.

Feature:

1. The mill pot makes two planetary movement, It enjoys high efficiency and small particle size under the high frequency percussion, linear collision force, friction force.( First in China)

2. Four different samples can be got at one time. It is convenient for the technologist to do the research and develop the new material.

3. Feed Granularity of Materials: Soil material 10mm, other materials

10mm, other materials 3mm.

3mm.

4. Wet or dry grinding method. Minimum Granularity of powder amounts to 0.06 um.

5. Frequency controlled, you can set the speed as per experiment effect.

6. Large turn disc revolution: 50-400rpm.

Small turn disc revolution: 100-800rpm.

Large planetary axis rotation: 100-800rpm.

Mill pot rotation: 200-1600rpm.

7. The planetary ball mill has timing power off, self-timing forward and inversion function. It can raise the efficiency by choosing one-way, alternately, continuously, time-setting operation.

8. Motor power: 0.4L, 2L, 4L: 0.75KW, 220V, 50Hz; 16L, 20L: 5.5KW, 380V, 50Hz.

9. Our planetary ball mill is functional which has low bary center, stable performance, compact structure, easy operation, reliable safety, low noise, and low wastage.

Advantages of Dual Planetary Ball Mill:

It is the ideal facility to acquire samples for research institutes , universities as well as enterprise laboratories (can acquire four samples in one experiment). If mated with vacuum ball milling tanks, it can grind samples in vacuum status. The product is extensively applied to in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

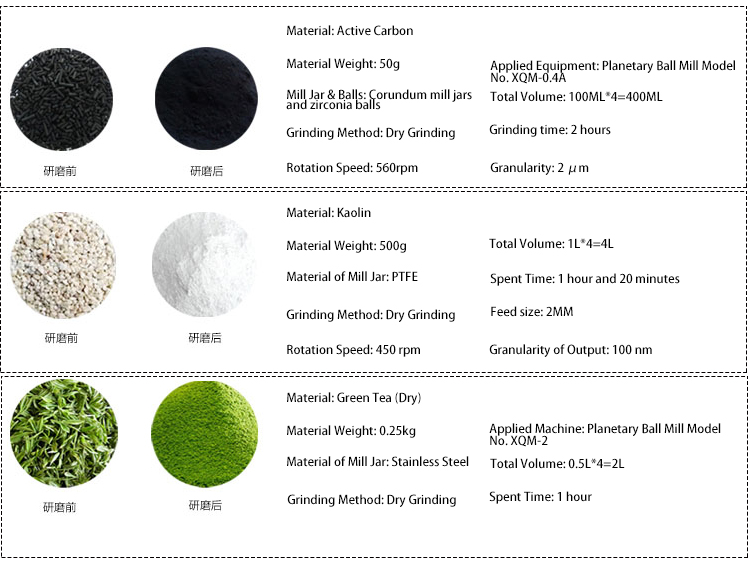

A wide range of powder can be ground by our planetary ball mill with different mill jars and balls, such as ore powder, fluorescent powder, glass powder, pigment powder and so on. Following are some powder samples for your reference.

Application Cases of Planetary Ball Mill:

Test Report of Grinding Granularity by Planetary Ball Mill:

Application Parameters

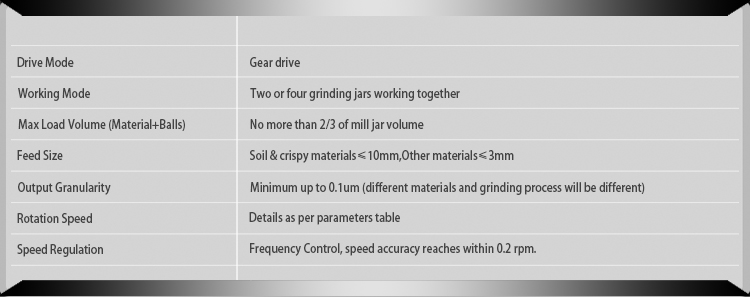

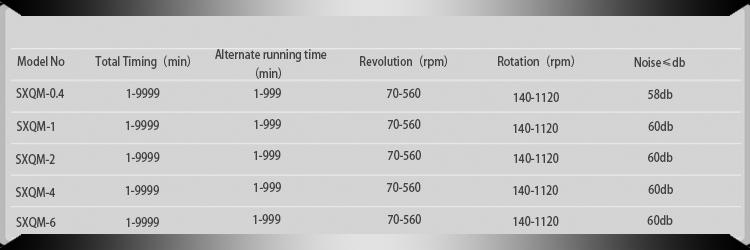

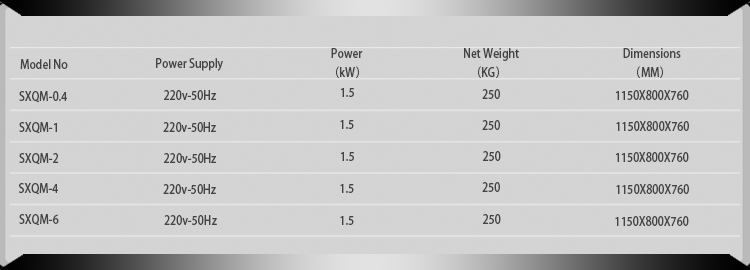

Main Parameters of High Energy Dual Planetary Ball Mill

Measurement of High Energy Dual Planetary Ball Mill

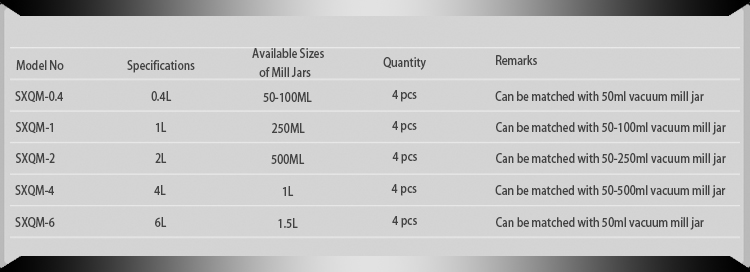

Available Sizes of Mill Jar for High Energy Dual Planetary Ball Mill

Mill Jars and Mill Balls:

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

1.Mill Jars:

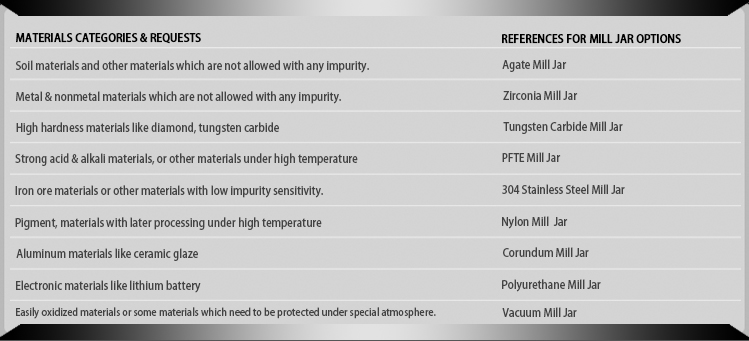

Suggestions for Matching Solution About Mill Jars & Materials:

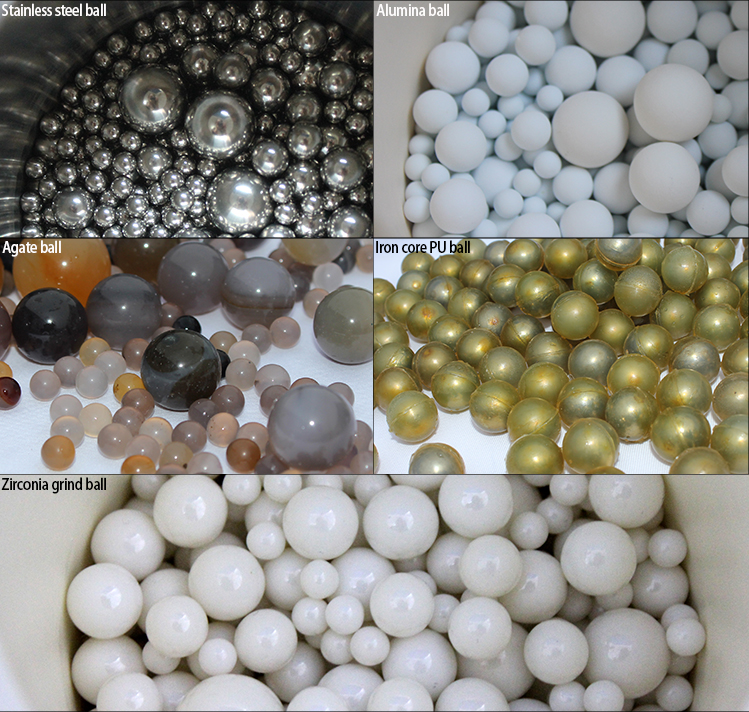

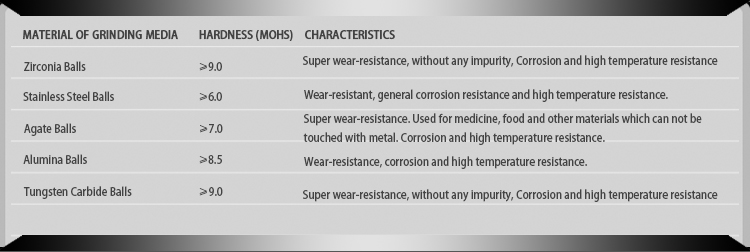

2.Mill Balls:

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

Suggestions for Matching Solution About Grinding Medium & Materials:

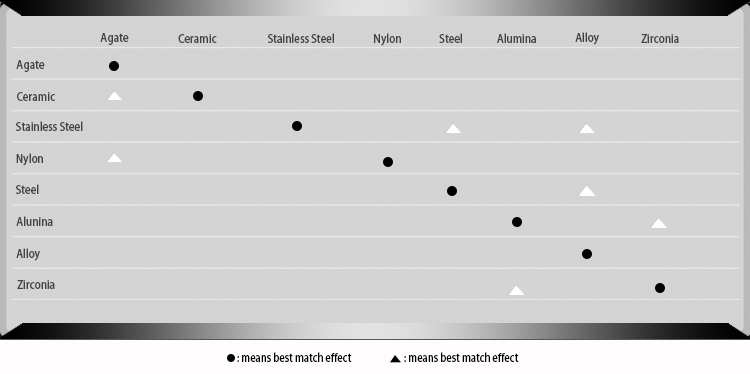

Suggestions for Matching Solution About Mill Jars & Mill balls:

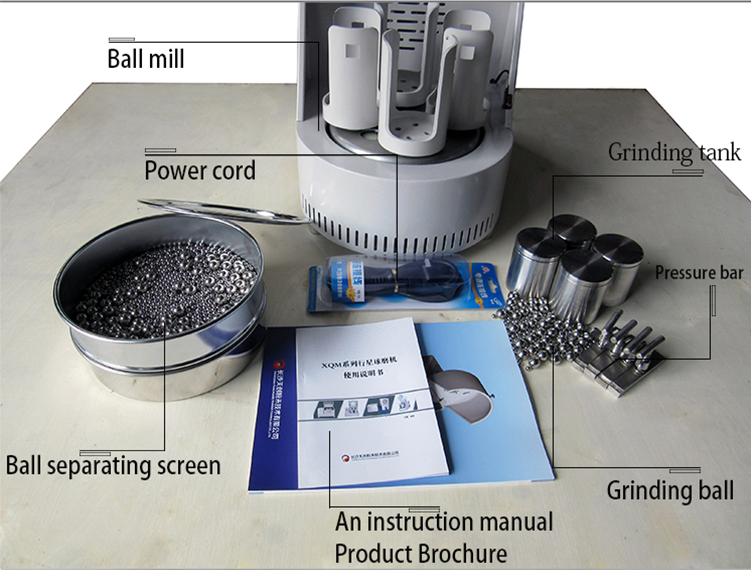

3.Pictures of Accessories & Spare Parts: